Raw Material : Gold Ore

Capacity : 1-150t/h

Hot Sale : 1-10T/H, 10-50T/H, 50-100T/H

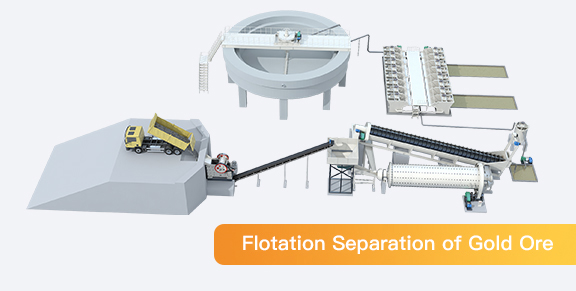

Processing Methods : Flotation And Gravity Separation

There are usually 5 types of gold mines: placer gold ore, polymetallic gold ore, rock gold ore, iron oxide gold ore, gold-bearing sulfide gold ore, etc.

Gold mining equipment is mainly used to separate gold ore in the mineral processing industry. The methods for processing gold ore include flotation, magnetic separation and gravity separation.

Gold mining equipment: including jaw crusher, ball mill, classifier, flotation cell, dryer, gold shaker table, spiral concentrator, etc.

Large pieces of gold ore need to go through processes such as coarse crushing and fine crushing to break into suitable particle sizes. The crushing process forms a closed loop. After being screened by the vibrating screen, materials that do not meet the requirements will be crushed twice until they meet the particle size requirements.

Materials with a size of 0-25 mm are evenly sent to the ball mill for grinding, and are screened by a spiral classifier. Materials that do not meet the requirements are sent to the ball mill for continued grinding; they are ground into finer particles to prepare for the next step of beneficiation;

At this stage, the specific mineral processing method isdetermined according to the material conditions. Core equipment at this stage: spiral chute, spiral classifier, shaker, flotation machine.

1Gravity Separation of Gold Ore: The gravity separation process relies on the combined action of medium fluid and various mechanical forces to create a comfortable loose layer and separation conditions to obtain particles of different densities and sizes. Since the density of gold minerals is much greater than that of gangue minerals, a gravity separation process should be used for gold ores containing gold particles. The gravity separation method is only applicable to monomer dissociated gold ore (placer gold).

2Flotation Separation of Gold Ore: First, feed the slurry into the flotation machine, add chemicals and stir thoroughly. While mixing, use air to attach the gold particles to the air bubbles. Bubbles floating on the surface are scraped off to separate gold particles and impurities. The process includes four parts: batching, stirring, aeration, and foam scraping.

Send the obtained gold powder into a dryer to dry it to obtain gold fine powder.

Shaking table beneficiation uses the combined action of symmetrical reciprocating motion of mechanical stone slabs and thin-layer inclined plane water flow on an inclined bed surface to loosely layer and zone minerals on the bed surface, thereby separating gold from other minerals according to different densities come out.

Advantages: The gold selection is stable and reliable, the distribution of the ore belt is clearly visible, the ore enrichment rate is high, and the required ore can be sorted in one go.

The spiral concentrator is installed vertically, and the slurry is naturally fed from high to low, generating inertial centrifugal force in the rotating inclined flow rate. According to the specific gravity, particle size and shape of the ore, the gold concentrate is separated using the gravity and centrifugal force of the cyclone separator.

Advantages: Lighter weight, Smaller footprint, Stable mineral processing, High recovery rate.

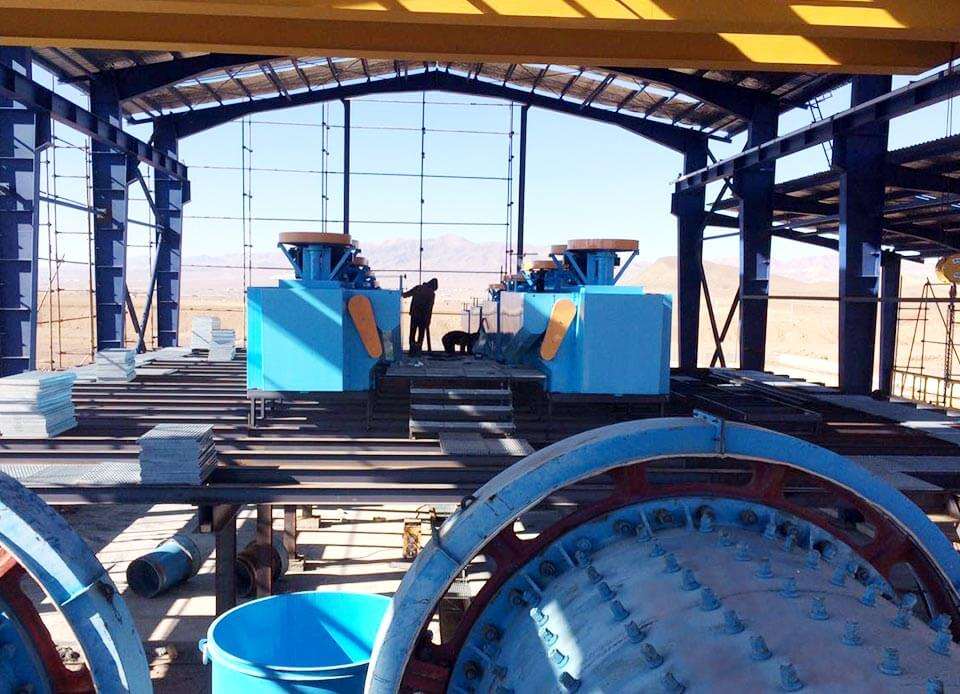

The flotation machine uses a motor V-belt to drive the impeller to rotate, producing centrifugal action and forming negative pressure. Froth flotation utilizes the hydrophobicity of gold to separate it from gangue, thereby recovering fine and ultra-fine gold particles.

Advantages: High degree of foam refinement, Flotation accuracy increased by 3-5%, Efficient operation.

In actual production, gold concentrate is often doped with other magnetic substances, such as iron impurities, and a magnetic separator is needed to separate the impurities before further finishing. Dynamic magnetic system design facilitates sorting, and the grade of raw ore can be increased by 1-4 times, thereby achieving the effect of efficient recovery of gold concentrate.

Advantages: Stable magnetic field strength, Low equipment energy consumption, Low failure rate.

Raw Material : Gold Ore

Feeding Size : <200mm

Raw Ore Grade : 5%

Capacity : 4t/h

Factory Visit Date: 2023/12

Raw Material : Gold Stone

Feeding Size : 300mm

Raw Ore Grade : 5%

Capacity : 5t/h

Factory Visit Date: 2021/03

FTM Machinery has established a comprehensive service delivery system to ensure stable operation and to save lots of trouble and maintenance costs for you.

Serve 160 countries around the world

Serve 160 countries around the world

Please feel free to write down your requirement in the form below. We will send detail product information and latest quotation to you.

Email : master@sinoftm.com 24 hours online

We will strictly protect the privacy of users'personal information and never disclose it.