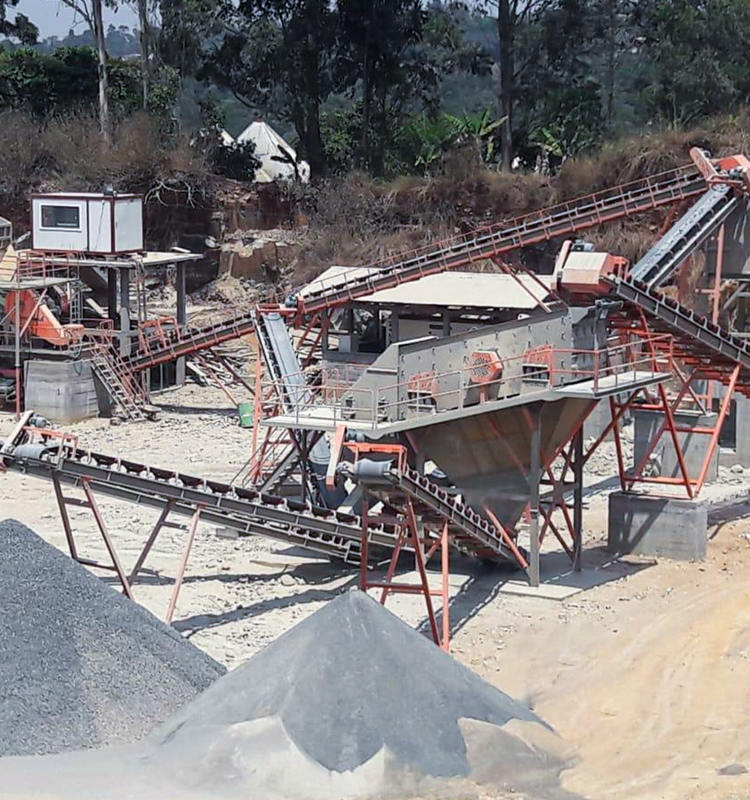

The stone crushing plant, also known as the sand and gravel production line, is composed of a variety of equipment. The design output is generally 30-800T/H. According to the customer's processing needs, there is a technical team to help tailor-make solutions. It has flexible configuration, large crushing ratio, good finished product particle shape, low needle-like content, and reduces costs by 20%.

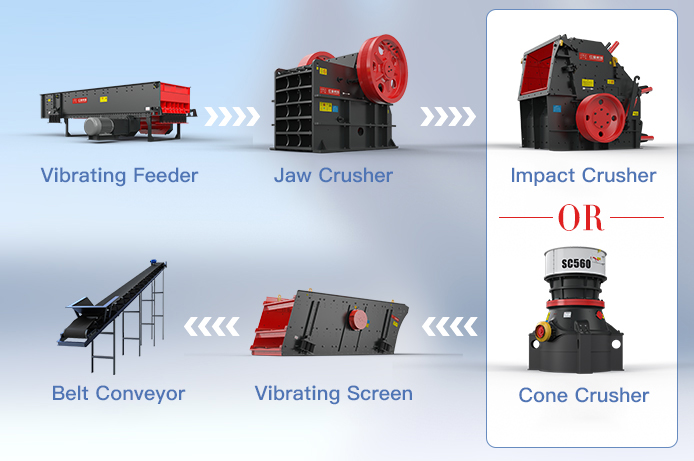

Usually it is composed of feeder, jaw crusher (coarse crushing), impact crusher/cone crusher (medium and fine crushing), screening machine, conveyor, centralized electronic control and other equipment.