HX series circular vibration tilting screen machine is a new type of circular vibrating screen product launched by FTM Group for heavy duty condition based on YA and YK series vibrating screen, combined with customers' on-site use and maintenance experience. Mature technology, accessories universal strong. Its vibration strength, high structural strength, and simple maintenance, long service life. Suitable for heavy, medium and fine screening and other screening operations. The sieving machine is ideal for handling the products after primary and secondary crushing, as well as for inspection screening in the process and final product screening.

HX series circular vibrating screen is a new type of circular vibrating screen product launched by FTM Group on the basis of YA and YK series vibrating screens, integrating customer site usage and maintenance .

15°-- 23°screen surface inclination selection range, can better adapt to the specific site conditions;

The shaker is an eccentric shaft + eccentric block structure, providing sufficient excitation force for transmission stability;

Thin oil lubricated vibrator, replace lubricating oil once half a year, Daily maintenance is easy;

Key parts of the design of wear-resistant protective layer, quickly replace after wear, prolong the service life of the equipment;

Belt wheel drive, can quickly adjust the equipment speed according to the field conditions;

Using special bearings for vibration equipment, longer life, escort for your screen division sequence.

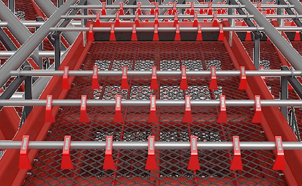

Screen body (Q355 side plate)

Spring support part

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding Size (mm) | Processing capacity(t/h) |

| 2HX1545 | 200 | 45-500 |

| 3HX1545 | 200 | 55-500 |

| 4HX1545 | 200 | 65-500 |

| 2HX1855 | 200 | 55-600 |

| 3HX1855 | 200 | 65-600 |

| 4HX1855 | 200 | 75-600 |

| 2HX2165 | 200 | 65-700 |

| 3HX2165 | 200 | 75-700 |

| 4HX2165 | 200 | 85-700 |

| 2HX2465 | 200 | 80-800 |

| 3HX2465 | 200 | 90-800 |

| 4HX2465 | 200 | 100-800 |

| 2HX2765 | 200 | 100-900 |

| 3HX2765 | 200 | 110-900 |

| 4HX2765 | 200 | 120-900 |

| 2HX3065 | 200 | 110-1200 |

| 3HX3065 | 200 | 120-1200 |

| 4HX3065 | 200 | 130-1200 |

| 2HX3075 | 300 | 120-1300 |

| 3HX3075 | 300 | 130-1300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.