HPM series multi-cylinder cone crusher is a new type of cone crusher which is suitable for crushing high hard materials and has strict requirements on the grain shape of products. This series is complete, matching the new generation of intelligent control system and Internet control system.

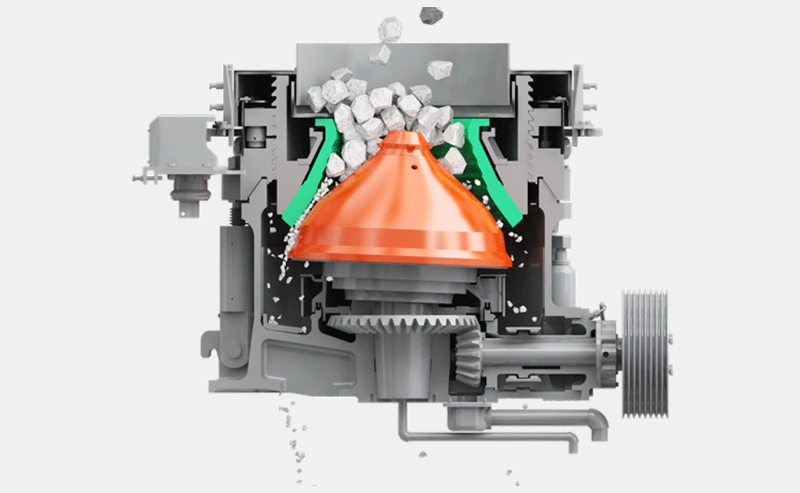

Laminated crushing: Ensure the cube shape

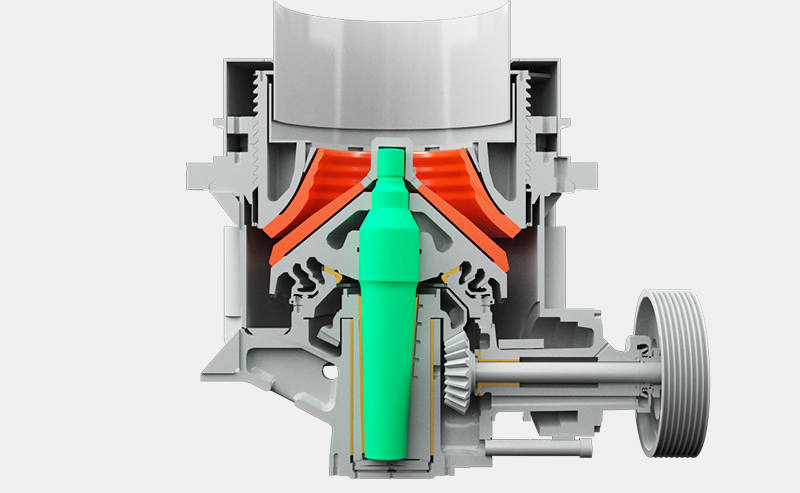

Positive pressure dust proof system: Effectively prevent dust and other sundries from entering the equipment and oil tank to avoid lubricating oil pollution

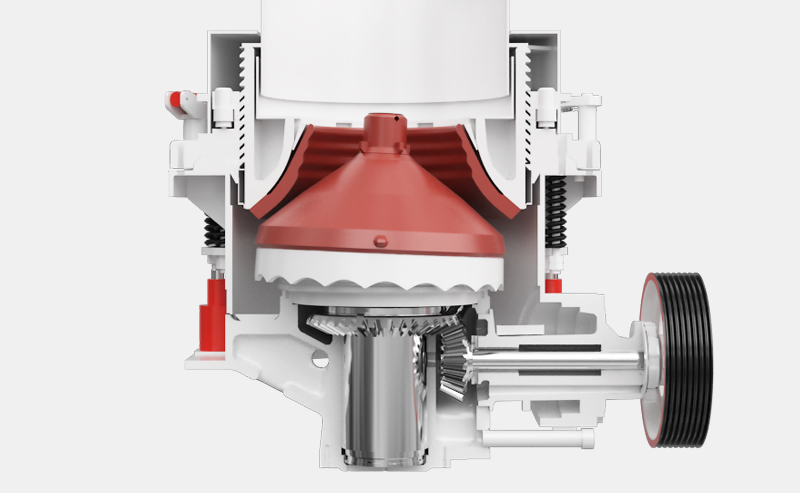

No glue packing, easy to change: Replacing lining board is economical and time saving

Zero degree spiral bevel gear: High transmission efficiency, quiet, prevent burning sleeve

The use of tin bronze bushing sliding bearing design enables it to have super high load capacity under high dust and high impact environment.

The installation and replacement of the lining does not need to pour the lining board glue, which more saves time, lower cost and more reliable to fixing.

It adopts spiral bevel gear design, high load capacity, stable transmission and low noise.

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Maximum Feeding size(mm) | Capacity(t/h) |

| HPM200 | C1 | 145 | 160~250 |

| C2 | 100 | 145~250 | |

| C3 | 75 | 120~250 | |

| F1 | 60 | 108~210 | |

| F2 | 45 | 81~210 | |

| HPM300 | C1 | 190 | 230~445 |

| C2 | 170 | 200~445 | |

| C3 | 120 | 180~445 | |

| C4 | 85 | 160~220 | |

| F1 | 40 | 140~220 | |

| HPM400 | C1 | 240 | 270~630 |

| C2 | 200 | 252~630 | |

| C3 | 160 | 243~630 | |

| C4 | 90 | 210~630 | |

| F1 | 75 | 162~370 | |

| F2 | 40 | 126~370 | |

| HPM500 | C1 | 270 | 365~790 |

| C2 | 230 | 328~790 | |

| C3 | 165 | 280~790 | |

| F1 | 105 | 202~450 | |

| F2 | 75 | 175~450 | |

| F3 | 42 | 158~450 | |

| HPM650 | C1 | 262 | 386~790 |

| C2 | 225 | 348~790 | |

| C3 | 175 | 300~790 | |

| F1 | 85 | 280~530 | |

| F2 | 42 | 220~530 | |

| HPM800 | C1 | 280 | 616~1100 |

| C2 | 240 | 522~1100 | |

| C3 | 214 | 495~1100 | |

| C4 | 175 | 380~1100 | |

| F1 | 125 | 328~730 | |

| F2 | 75 | 270~730 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

SC Series Single Cylinder Hydraulic Cone Crushers

SC series cone crusher is developed on the basis of absorbing the world's most advanced technology and integrating the company's many years of design experience.

READ MORE

SC Series Single Cylinder Hydraulic Cone Crushers

SC series cone crusher is developed on the basis of absorbing the world's most advanced technology and integrating the company's many years of design experience.

READ MORE

SC/H800i Series Single Cylinder Hydraulic Cone Crushers

SC/H800i series single cylinder cone crusher of FTM Group is a new generation product comprehensively upgraded on the basis of SC series cone crusher according to market demand and focusing on the forefront of the times.

READ MORE

SC/H800i Series Single Cylinder Hydraulic Cone Crushers

SC/H800i series single cylinder cone crusher of FTM Group is a new generation product comprehensively upgraded on the basis of SC series cone crusher according to market demand and focusing on the forefront of the times.

READ MORE