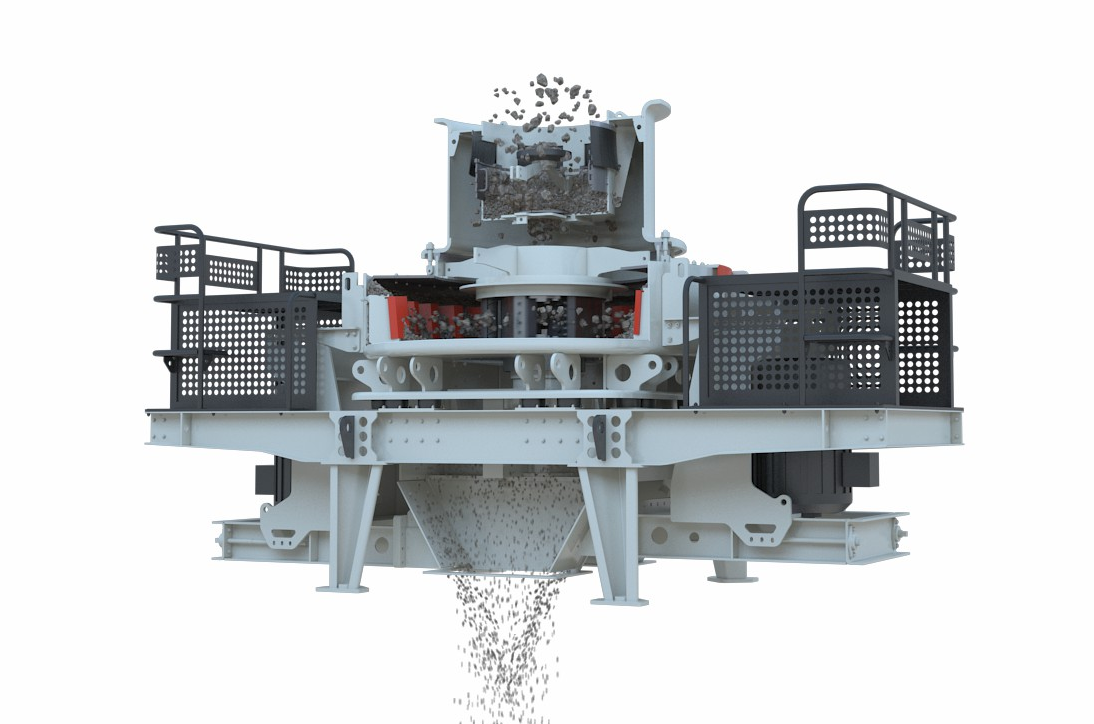

The VSI A7 series impact sand maker with deep cavity is a new generation product that not only draws on the advanced technology of similar products at home and abroad, but also has a number of independent research and development results. In the application of large and super large machine-made sand and fine aggregate production lines, it has demonstrated extremely powerful performance.

The VSI A7 series impact sand maker with deep cavity is also suitable for applications in the fields of metal/non-metal ore, metallurgical slag,and material recovery. VSIA7 series sand making machines provide high-quality aggregates with more reasonable gradation and better grain shape to meet high-quality specifications.

The VSI A7 series impact sand maker has higher output efficiency than other types of crushers. It can not only process all kinds of natural stone materials, but also can make mechanical sand with waste concrete, waste lime, other waste residue and other materials, effectively alleviating the shortage of sand and gravel aggregates because of the shortage of natural yellow sand resources. Strong sealing, advanced pulse dust removal device can effectively control the emission of sand dust and reduce the pollution of air, thus achieving green sand production. The product is in the form of a cube with a discharge size of 0-5 mm.

By adjusting the hopper feeding device, can easily switch between the two modes of "falling feeding + center feeding" and "full center feeding". Adjusting the angle of the distribution plate can avoid the direct impact of the material on the impeller and reduce the abnormal wear of the impeller.

The design of the large discharge port makes the material unloading more smoothly, which effectively prevents material blockage, avoids abnormal damage to the equipment, and improves the crushing efficiency.

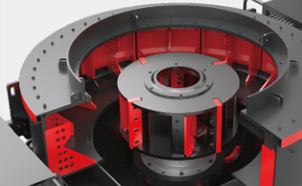

Taking into account the characteristics of wear resistant ambient guard board and rock self-breaking, the developed low-os swear structure.Reduce the cost of wearing and increase the crushing efficiency.

1. The adoption of new technology and new materials greatly prolongs the service life of wearing parts and effectively reduces downtime and maintenance time and wear of wearing parts.

2. After the peripheral guard plate is partially worn, it can be used up and down, with high utilization rate and lower operating cost.

The adoption of new technology and new materials greatly prolongs the service life of wearing parts and effectively reduces downtime and maintenance time and wear of wearing parts.

The modular design of the main shaft assembly,thin oil lubrication and grease lubrication; a combination of multiple sealing forms is designed, and the sealing effect is more reliable.

Technical Specifications

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sand Making | Sand Shaping | Motor Power(kw) |

| Throughput (t/h) | |||

| VSIA7 400 | 260-285 | 314-345 | 2×200 |

| VSIA7 500 | 340-370 | 405-480 | 2×250 |

| VSIA7 630 | 450-488 | 540-590 | 2×315 |

| VSIA7 800 | 556-603 | 652-703 | 2×400 |

Note:Processing Capacity May Vary With Different Materials And Feeding Sizes.

VSI Series Sand Making Machine

VSI series high efficiency vertical shaft impact crusher(sand maker)is the stone crushing equipment with domestic and international advanced technologies, which is researched on the basis of Germany advanced technology, combining the actual demand of China sand—making industry.

READ MORE

VSI Series Sand Making Machine

VSI series high efficiency vertical shaft impact crusher(sand maker)is the stone crushing equipment with domestic and international advanced technologies, which is researched on the basis of Germany advanced technology, combining the actual demand of China sand—making industry.

READ MORE

HVI Series Sand Making Machine

The HVI series sand maker is a new generation of products that our company introduces German technology, absorbs the domestic and foreign similar products' advanced technology development, and has many spontaneous R & D characteristics at the same time, which integrates all kinds of crushing modes,become the core equipment of mechanism sand industry.

READ MORE

HVI Series Sand Making Machine

The HVI series sand maker is a new generation of products that our company introduces German technology, absorbs the domestic and foreign similar products' advanced technology development, and has many spontaneous R & D characteristics at the same time, which integrates all kinds of crushing modes,become the core equipment of mechanism sand industry.

READ MORE