According to the working principle, the coal dryer is a rotary drum dryer. It is a very mature drying equipment produced by mining equipment manufacturers. It is suitable for drying coal slime, clean coal, and coal. Lignite, clean coal, sludge, magnetic, heavy, and float concentrates of metal and non-metallic minerals, and clay in the cement industry. It is characterized by high productivity and easy operation.

The barrel is a horizontal rotary cylinder, and its interior is welded with various copy plates with different angles in a staggered arrangement from front to back.According to the needs of users, the interior of the coal dryer barrel can be designed and equipped with refractory materials for temperature insulation. The material end is equipped with a door ring and a spiral copy plate to prevent the material from being poured.

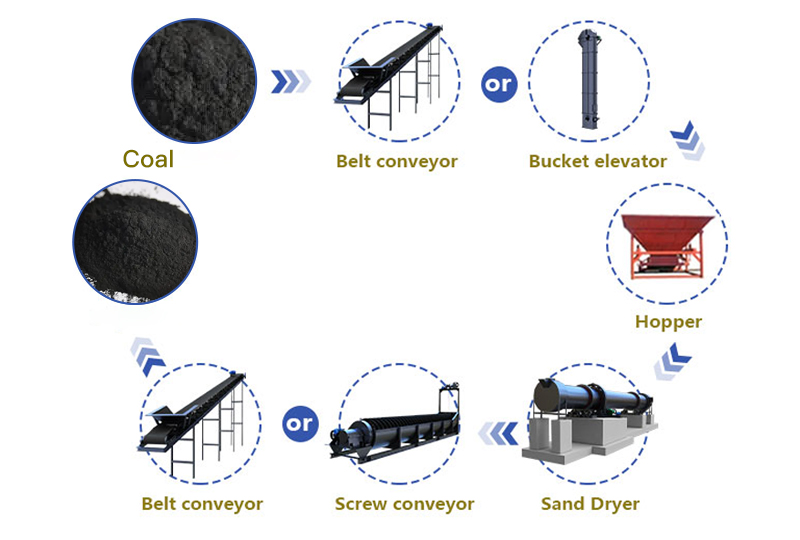

The coal is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The material is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

High thermal efficiency, stable drying quality.

Long parts life, not easy to wear.

Simple structure, a small footprint.

Uniform vibration, airproof setting.

Exchange heat fully, lower the energy consumption.

Simple operation, environmental protection and energy saving.

10T/H Coal Dryer In South Africa

Technical Specifications

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Ø 1.2×8 | 1.9-2.4 | 700-800 |

| Ø1.2 ×10 | 2.4-3 | 700-800 |

| Ø 1.5×12 | 4.5-5.7 | 700-800 |

| Ø 1.5×14 | 5.3-6.6 | 700-800 |

| Ø1.5×15 | 5.7-7.1 | 700-800 |

| Ø 1.8×12 | 6.5-8.1 | 700-800 |

| Ø 1.8×14 | 7.6-9.5 | 700-800 |

| Ø 2.2×12 | 9.7-12.2 | 700-800 |

| Ø 2.2×14 | 11.4-14.2 | 700-800 |

| Ø 2.2×16 | 13-16.2 | 700-800 |

| Ø 2.4×14 | 13.5-16.9 | 700-800 |

| Ø 2.4×18 | 17.4-21.7 | 700-800 |

| Ø 2.4×20 | 19.3-24.1 | 700-800 |

| Ø 2.4×22 | 21.2-26.5 | 700-800 |

| Ø 2.6×24 | 27.2-34 | 700-800 |

| Ø 3×20 | 30.1-37.7 | 700-800 |

| Ø 3×25 | 37.7-47.1 | 700-800 |

| Ø 3.2×25 | 42.9-53.6 | 700-800 |

| Ø 3.6×28 | 60.8-76 | 700-800 |