The MTF series of wheel-type mobile production lines fully cover the application fields of hard rock, soft rock, and construction waste with a processing capacity of 100-300 tons per hour.

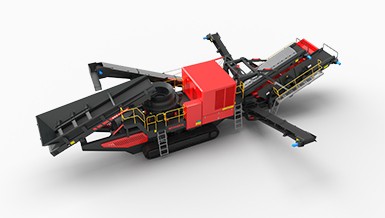

The overall appearance of the mobile station is beautiful, the workmanship is exquisite, the host is equipped with the latest technology, the performance is stable and reliable, and the output is high. A large number of belt conveyors which are assembled on the trailer eliminate the need for on-site transfer and external belt conveyors, and the work site is tidy and organized; Each mobile station is equipped with a crawler plate device to ensure that the equipment arrives at the site quickly for installation and commissioning, and reduces the concrete foundation preparation time.

The main equipment on the production line are all high-performance machines produced with the latest industry technology, with high efficiency, high output, and stable and reliable operation.

The feeder adopts a vibrating motor to provide excitation force, and accurately controls the feeding amount through a frequency converter to maximize the production capacity of the equipment.

The jaw crusher adopts a wedge to adjust the discharge opening, which is easy to operate. The integral motor bracket, the belt has good force and long life.

The cone crusher adopts an automatic control system, which is easy to operate, stable, reliable, high in efficiency and good in particle shape.

The impact crusher adopts the refined design of the rotor and cavity, the speed and power are reasonably matched to meet the different application options of coarse crushing, medium and fine crushing and material recovery.

The vibrating screen adopts thin oil lubrication, and the oil change interval is as long as 1200 hours, thelubrication effect is good, and the equipment downtime is short.

The MTF series mobile production line adopts modular and universal design, with high structural strength and strong versatility.

The feeder adopts frequency conversion control, and the feeding amount of the feeder can be adjusted according to different conditions to give full play to the production capacity of the production line.

The main equipment on the production line are all high-performance machines produced with the latest industry technology, with high efficiency, high output, few failures, convenient operation and maintenance.

The front and back connection design of the maintenance platform is convenient for the operator to observe the equipment operation in time. Inclined up and down escalators, wider pedals, safer and more convenient than upright ladders.

Each equipment of the mobile production line is equipped with a vehicle-mounted belt conveyor, which does not need to be disassembled. Work can be started quickly when arriving at the site, and the work site is clean and orderly.

Electronic control system assembled on the trailer Each device of the mobile production line is equipped with an independent electronic control system, which is easy to operate. The whole machine can be debugged quickly when it arrives on site.

Technical Specifications

Wheeled Mobile Jaw Crushing Station

Wheeled Mobile Impact Crushing Station

Model FTM938HD86 and FTM1149HD98

| Model | FTM938HD86 | FTM1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model FTM1349HD110 and FTM1349HD125

| Model | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

Model FTM938F1210 and FTM938F1214 and FTM1149F1315

| Model | FTM938F1210 | FTM938F1214 | FTM1149F1315 |

| Transportation length(mm) | 12000 | 12000 | 13900 |

| Transportation Width(mm) | 2550 | 2550 | 2900 |

| Transportation Height(mm) | 3900 | 3900 | 4450 |

| Maximum Length(mm) | 12500 | 12500 | 13900 |

| Maximum Width(mm) | 3250 | 3260 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW |

| iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 |

Model FTM938F1110 and FTM1349F1315

| Model | FTM938F1110 | FTM1349F1315 |

| Transportation length(mm) | 15450 | 15450 |

| Transportation Width(mm) | 2950 | 2950 |

| Transportation Height(mm) | 4500 | 4500 |

| Maximum Length(mm) | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3250 |

| Maximum Height(mm) | 5200 | 5200 |

| Weight(t) | 62 | 62 |

| Impact crusher | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 400 | 700 |

| Capacity(t/h) | 112 | 280 |

| Vibrating Feeder | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-12 |

Mobile Jaw Crusher

The mobile jaw crusher is mainly composed of a feeder, a jaw crusher, a belt conveyor and a vibrating screen.

READ MORE

Mobile Jaw Crusher

The mobile jaw crusher is mainly composed of a feeder, a jaw crusher, a belt conveyor and a vibrating screen.

READ MORE

Mobile Stone Crusher

Mobile Stone crushers include crawler-type mobile crusher and wheeled mobile crusher.

READ MORE

Mobile Stone Crusher

Mobile Stone crushers include crawler-type mobile crusher and wheeled mobile crusher.

READ MORE