H5M series German version of intelligent millis a new product with high technical level developed by FTM Group's scientific research institute on the basis of more than 40 years of experience in the research and development of mil ing equipment, according to the actual situation of users using mining equipment for many years, in response to the needs of the development of them i ing industry, absorbing the cutting-edge domestic and foreign mature mining technology and concepts, and developing new products with high technological level with great dedication.

Widely used in metallurgy, building materials, chemical industry, mining and other industries, it can process non-flammable and explosive materials with Moh's hardness <9.3 and humidity below 6%, such as limestone, feldspar, calcite, talc, barite, rare earth, bauxite, phospho rite, iron oxide red, dolomite, granite, bituminous coal, gypsum and soon.

The grinding line can be paired with PLC system to optimise the mil discharge logic, accurately control the feeding volume, improve production efficiency, simplify the operation process and save alot of manpower.

The use of high-pressure centrifugal fans, energy-saving and efficient, can ensure that as table windpower is provided for system operation.

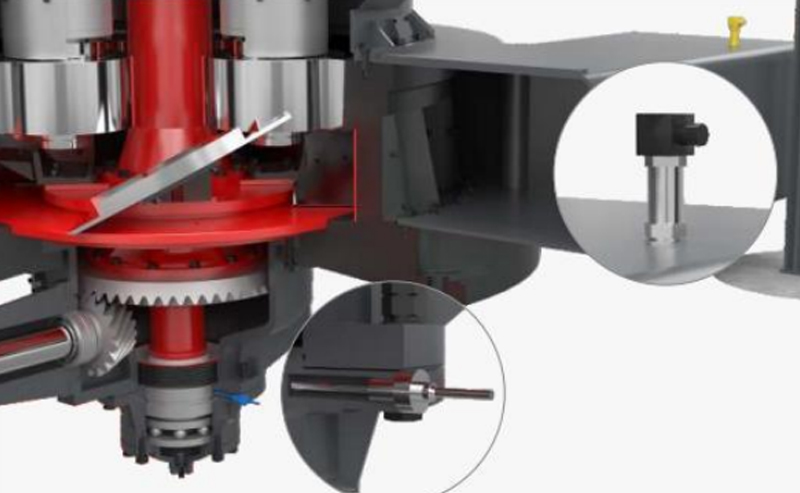

Unique spindle and grinding roller assembly thin oil lubrication structure, lubrication effect is significantly improved, bearing life of up to 3-10 years, refuelling cycle of up to 6 months, maintenance is simple.

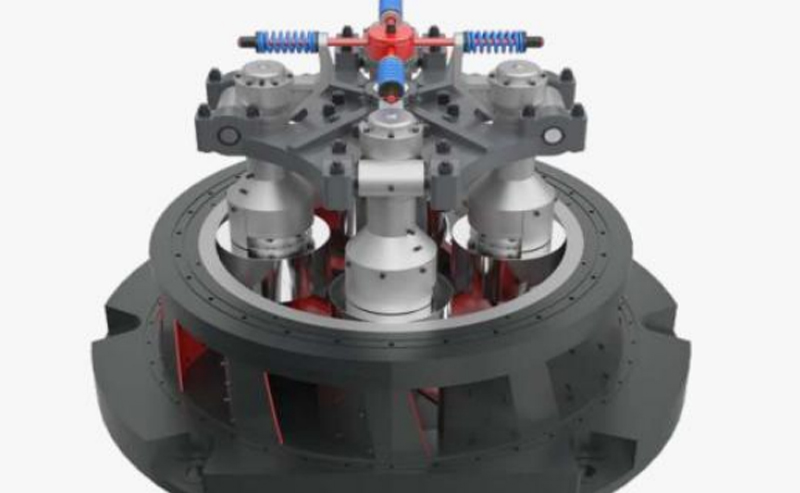

With the linkage pressure technology of grinding rollers, the crushing pressure can be increased to 2. 5 tonnes, which significantly improves the ablity to crush hard materials, and the capacity of ordinary materials can be increased by more than 10%.

V-belt plus spiral bevel gear drive,compact structure, smooth transmission, lownoise.

Equipped with special pulse dust collector, the dust removal efficiency can be 99. 9%, the emission concentration is≤10mg/Nm, which is better than the national environmental protection emission standard, and realises dustfree operation in the production workshop.

High-pressure Centrifugal fans

Thin Oil Lubrication Structure

Grinding Roller

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Capacity (t/h) |

Power of main machine (kW) |

| H5M115 | 1.2-15 | 55 |

| H5M145 | 2-26 | 90/110 |

| H5M178 | 3-38 | 185/200 |

| H5M198 | 6-45 | 280/315 |

| H5M218 | 7-55 | 315/355 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

HGM German Version Raymond Mill

HGM series German Raymond mill is a new product with high technical level developed by FTM Group Research Institute on the basis of more than 40 years of experience in grinding equipment research and development

READ MORE

HGM German Version Raymond Mill

HGM series German Raymond mill is a new product with high technical level developed by FTM Group Research Institute on the basis of more than 40 years of experience in grinding equipment research and development

READ MORE

Raymond Mill

Raymond mill is widely used in high-fine powder processing of more than 280 kinds of non-metallic ore materials with a Mohs hardness of not more than 9.3 and non-flammable and explosive mineral, chemical and construction industries with a humidity of 6% or less.

READ MORE

Raymond Mill

Raymond mill is widely used in high-fine powder processing of more than 280 kinds of non-metallic ore materials with a Mohs hardness of not more than 9.3 and non-flammable and explosive mineral, chemical and construction industries with a humidity of 6% or less.

READ MORE