TD series belt conveyor is a kind of general conveying equipment, which is composed of single or multiple units to synthesize the conveying system. It is widely used in mining, metallurgy, coal and other departments to convey loose materials or finished articles. Applicable ambient temperature is - 10 ℃ to+40 ℃.

After the belt of the TD belt conveyor passes through the rollers at both ends, the two ends are connected together by a tape clip or vulcanization method to form a closed loop structure. The tape is supported by the upper and lower rollers, and the tensioning device tightens the tape to have a certain tension. When the active roller is driven by the motor to rotate, the friction between the active roller and the tape drives the tape to run continuously, thereby unloading the cargo loaded on the tape from the unloading roller.

Strong transportation capacity, long transportation distance, stable operation, reliable work, high productivity, easy to realize automation and centralized control;

The conveying range is wide. It can continuously convey wet, dry, powdery, blocky and finished articles, and can receive or discharge materials to multiple points;

Simple structure, easy maintenance, strong interchangeability and versatility of main parts.

Technical Specifications

| Belt width (mm) |

Converying speed (m/s) |

Concerying capacity (t/h) |

| 400 | 1.25-2.0 | 30-60 |

| 500 | 1.25-2.0 | 40-80 |

| 650 | 1.25-2.0 | 80-120 |

| 800 | 1.25-2.0 | 120-200 |

| 1000 | 1.25-2.0 | 200-320 |

| 1200 | 1.25-2.0 | 290-480 |

| 1400 | 1.25-2.0 | 400-680 |

| 1600 | 1.25-2.0 | 600-1080 |

| 1800 | 1.0-2.0 | 800-1500 |

| 2000 | 1.0-2.0 | 1000-2000 |

| 2400 | 1.0-2.0 | 1500-3000 |

CJ Series European Type Jaw Crusher

The CJ series jaw crusher is with excellent performance introduced by Henan Fote Heavy Machinery Co.,Ltd. based on the needs of customers.

READ MORE

CJ Series European Type Jaw Crusher

The CJ series jaw crusher is with excellent performance introduced by Henan Fote Heavy Machinery Co.,Ltd. based on the needs of customers.

READ MORE

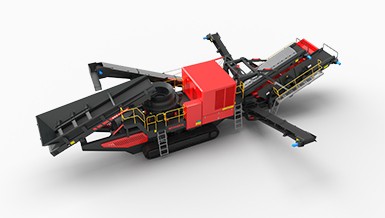

Mobile Stone Crusher

Mobile Stone crushers include crawler-type mobile crusher and wheeled mobile crusher.

READ MORE

Mobile Stone Crusher

Mobile Stone crushers include crawler-type mobile crusher and wheeled mobile crusher.

READ MORE