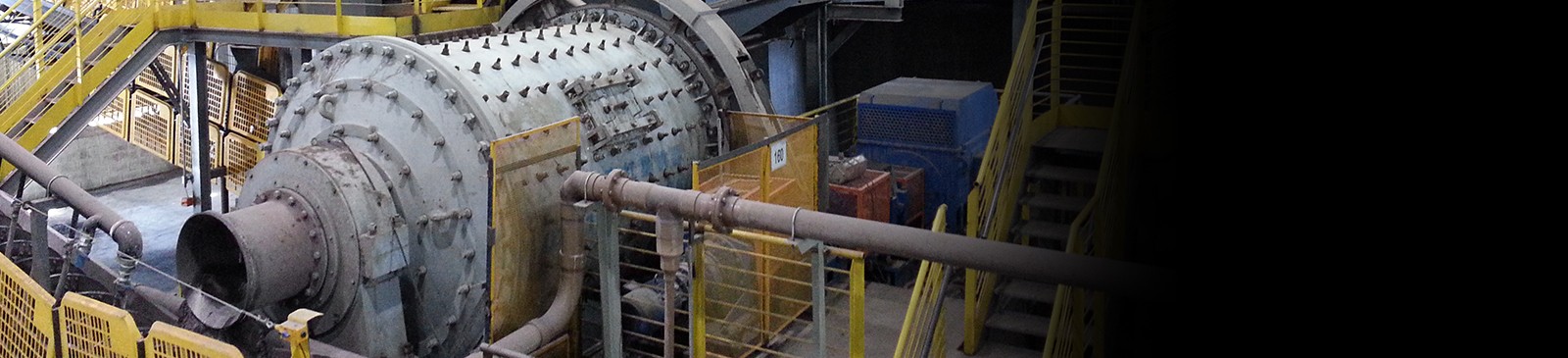

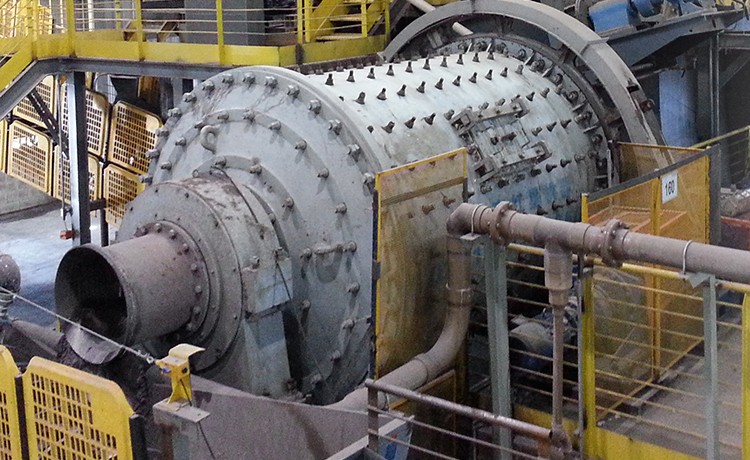

Rod mill is the key equipment for grinding after materials are crushed at crushing plant. Rod mill is an efficient crushing machine for grinding various materials into powder. Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills. Rod mills crush generally coarser than those produced in Ball mill, and rod mills are well suited to handle coarser feed and to control the bigger size of the product.

The rod mill adopts advanced controllable feeding and discharging technology, which changes the traditional surface contact into line contact. When the frame rotates, centrifugal force is produced. At the same time, the steel rods are carried to some height and then fall to grind and strike the material. After grinded in the crushing chamber, the powder is discharges by output material board.

Energy saving is 50% higher than traditional rod mills and rod mill has stable operation and adjustable fineness of discharge.

It is made of wear-resistant materials, which is durable and has a low failure rate.

The rod mill cylinder is fully enclosed and sealed to reduce dust pollution.

Lubrication design is reasonable, having high safety performance and sound insulation, and reducing noise pollution.

Technical Specifications

| Model | Feeding size (mm) |

Discharging size (mm) |

Processing capacity (t/h) |

| MBS0918 | ≤25 | 0.833-0.147 | 0.62-3.2 |

| MBS0924 | ≤25 | 0.833-0.147 | 0.81-4.3 |

| MBS1224 | ≤25 | 0.833-0.147 | 1.1-4.9 |

| MBS1530 | ≤25 | 0.833-0.147 | 2.4-7.5 |

| MBS1830 | ≤25 | 0.833-0.147 | 4.8-11.6 |

| MBS2130 | ≤25 | 0.833-0.147 | 14-35 |

| MBS2136 | ≤25 | 0.833-0.147 | 19-43 |

| MBS2430 | ≤50 | 0.833-0.147 | 25-65 |

| MBS2736 | ≤50 | 0.833-0.147 | 32-86 |

| MBS2740 | ≤50 | 0.833-0.147 | 32-92 |

| MBS3245 | ≤50 | 0.833-0.147 | 64-180 |

Wet Pan Mill

The wet pan mill can be used for the grinding operations of gold, silver, copper, iron, molybdenum, quartz and other ores, especially in the grinding work of various vein gold mines, rock gold mines, placer gold mines, and associated gold mines.

READ MORE

Wet Pan Mill

The wet pan mill can be used for the grinding operations of gold, silver, copper, iron, molybdenum, quartz and other ores, especially in the grinding work of various vein gold mines, rock gold mines, placer gold mines, and associated gold mines.

READ MORE

Ball Mill

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings, and glass ceramics. Dry or wet grinding of various ores and other materials.

READ MORE

Ball Mill

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings, and glass ceramics. Dry or wet grinding of various ores and other materials.

READ MORE