Industrial dryer machine in mineral processing. The removal of water from solid materials by thermal drying plays a significant role in modern mineral processing. A great number of dryer types are available.

Extracted ore, whatever the mineral, is usually first crushed and then finally must be dried. Drying is a critical aspect of mineral processing; the ability to control moisture levels from ore to final product helps reduce transportation costs, simplify downstream processing and produce refined products.

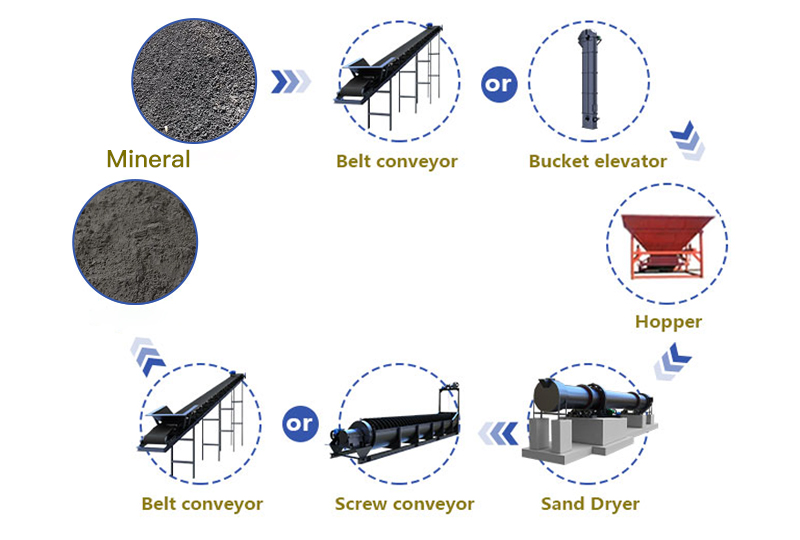

The mineral is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The material is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

The cylinder runs smoothly and reliably: the cylinder is made of steel material, which has the characteristics of high hardness and high toughness.

The new type of lifting plate device: the material is completely uniform in the radial section of the dryer, making full use of heat energy.

Strong carrying capacity: the base is made of cast steel, and the rolling ring fits well, and the rotation is stable.

10T/H Iron Ore Dryer Machine in Jordan

Technical Specifications

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Ø 1.2×8 | 1.9-2.4 | 700-800 |

| Ø1.2 ×10 | 2.4-3 | 700-800 |

| Ø 1.5×12 | 4.5-5.7 | 700-800 |

| Ø 1.5×14 | 5.3-6.6 | 700-800 |

| Ø1.5×15 | 5.7-7.1 | 700-800 |

| Ø 1.8×12 | 6.5-8.1 | 700-800 |

| Ø 1.8×14 | 7.6-9.5 | 700-800 |

| Ø 2.2×12 | 9.7-12.2 | 700-800 |

| Ø 2.2×14 | 11.4-14.2 | 700-800 |

| Ø 2.2×16 | 13-16.2 | 700-800 |

| Ø 2.4×14 | 13.5-16.9 | 700-800 |

| Ø 2.4×18 | 17.4-21.7 | 700-800 |

| Ø 2.4×20 | 19.3-24.1 | 700-800 |

| Ø 2.4×22 | 21.2-26.5 | 700-800 |

| Ø 2.6×24 | 27.2-34 | 700-800 |

| Ø 3×20 | 30.1-37.7 | 700-800 |

| Ø 3×25 | 37.7-47.1 | 700-800 |

| Ø 3.2×25 | 42.9-53.6 | 700-800 |

| Ø 3.6×28 | 60.8-76 | 700-800 |

Chat Online

Chat Online  Leave Message

Leave Message