HGM series German Raymond mill is a new product with high technical level developed by FTM Group Research Institute on the basis of more than 40 years of experience in grinding equipment research and development, according to the actual situation of users using grinding equipment for the development of grinding industry, absorbing sophisticated and mature grinding technology and concept at home and abroad.

Split modular structure, easy maintenance

Coupling reducer transmission form, compact structure

Brand reducer, reliable quality

Separate grinding roller, special wear-resistant shovelhead structure, improve the grinding efficiency, but also reduce the replacement cost of wear parts by more than 50%.

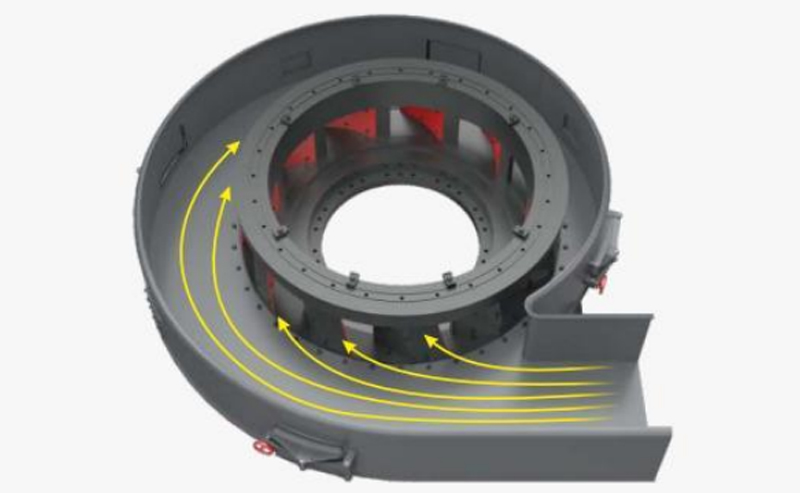

With no resistance volute and curved air duct, the wind resistance at the air inlet of the entire closed-circuit circulation system is greatly reduced, thereby increasing the production capacity by 15%.

Add large cyclone powder collector, combined with closed air feeder, greatly improve the yield of powder, reduce the return of powder.

Split Modular Design

Resistance-Free Volute with Curved Air Duct

Separate Grinding Roller, Special Wear-Resistant Shovel Head Structure

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Capacity (t/h) |

Power of main machine (kW) |

| HGM88 | 0.4-5 | 22 |

| HGM95 | 0.6-7 | 37 |

| HGM120 | 1.2-15 | 55 |

| HGM130 | 1.6-21 | 75 |

| HGM138 | 2-25 | 90 |

| HGM160 | 2.7-28 | 132 |

| HGM175 | 3-35 | 185 |

| HGM190 | 5-40 | 250/280 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

SFLM Series Ultra-fine Vertical Grinding Mill

SFLM series ultrafine vertical grinding machine is based on HLM vertical grinding machine, combined with related technologies from Germany,

READ MORE

SFLM Series Ultra-fine Vertical Grinding Mill

SFLM series ultrafine vertical grinding machine is based on HLM vertical grinding machine, combined with related technologies from Germany,

READ MORE

Raymond Mill

Raymond mill is widely used in high-fine powder processing of more than 280 kinds of non-metallic ore materials with a Mohs hardness of not more than 9.3 and non-flammable and explosive mineral, chemical and construction industries with a humidity of 6% or less.

READ MORE

Raymond Mill

Raymond mill is widely used in high-fine powder processing of more than 280 kinds of non-metallic ore materials with a Mohs hardness of not more than 9.3 and non-flammable and explosive mineral, chemical and construction industries with a humidity of 6% or less.

READ MORE