The gypsum dryer is mainly used for desulfurization gypsum with water content exceeding 30% to be less than 12%. The gypsum dryer is mainly composed of a rotating body, a lifting plate, a rotating device, a supporting device, and a sealing ring. The utility model has the advantages of reasonable structure, excellent production, high output, low energy consumption, and convenient operation.

Desulfurization gypsum processing and utilization are very significant, which not only strongly promotes the further development of the national environmental recycling economy, but also greatly reduces the amount of mining gypsum and protects resources.

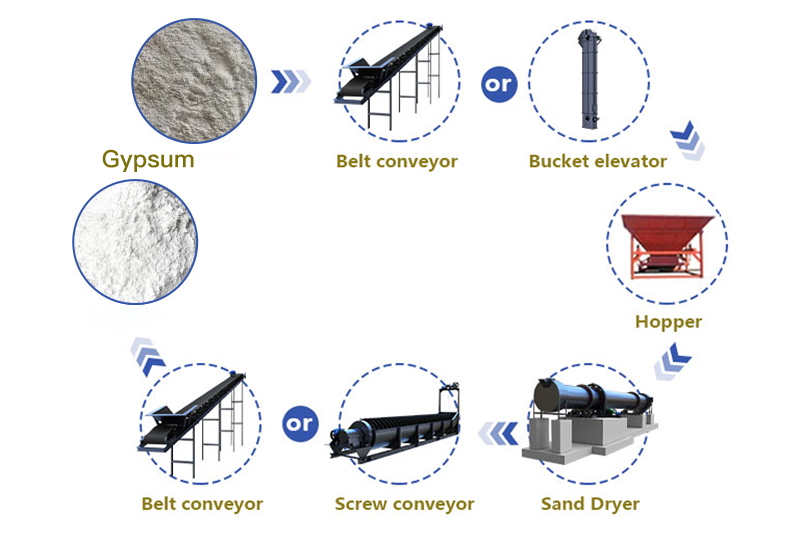

The gypsum is sent to the hopper by a belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The material is added from the higher end, and the heating medium enters from the lower end, and is in countercurrent contact with the material. When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end. In addition, dust collectors can also be used to reduce dust in the drying system.

The cylinder runs smoothly and reliably: the cylinder is made of steel material, which has the characteristics of high hardness and high toughness.

The new type of lifting plate device: the material is completely uniform in the radial section of the dryer, making full use of heat energy.

Strong carrying capacity: the base is made of cast steel, and the rolling ring fits well, and the rotation is stable.

50T/H Gypsum Drying Plant in South Africa

Technical Specifications

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Ø 1.2×8 | 1.9-2.4 | 700-800 |

| Ø1.2 ×10 | 2.4-3 | 700-800 |

| Ø 1.5×12 | 4.5-5.7 | 700-800 |

| Ø 1.5×14 | 5.3-6.6 | 700-800 |

| Ø1.5×15 | 5.7-7.1 | 700-800 |

| Ø 1.8×12 | 6.5-8.1 | 700-800 |

| Ø 1.8×14 | 7.6-9.5 | 700-800 |

| Ø 2.2×12 | 9.7-12.2 | 700-800 |

| Ø 2.2×14 | 11.4-14.2 | 700-800 |

| Ø 2.2×16 | 13-16.2 | 700-800 |

| Ø 2.4×14 | 13.5-16.9 | 700-800 |

| Ø 2.4×18 | 17.4-21.7 | 700-800 |

| Ø 2.4×20 | 19.3-24.1 | 700-800 |

| Ø 2.4×22 | 21.2-26.5 | 700-800 |

| Ø 2.6×24 | 27.2-34 | 700-800 |

| Ø 3×20 | 30.1-37.7 | 700-800 |

| Ø 3×25 | 37.7-47.1 | 700-800 |

| Ø 3.2×25 | 42.9-53.6 | 700-800 |

| Ø 3.6×28 | 60.8-76 | 700-800 |