Application: sawdust, wood chips, grass, straw, corn cobs, cattle bones, shells, bamboo chips, paper scraps, wine residue, sauce residue, sweet potato residue, fruit residue, Chinese medicine residue, etc.'

The biomass dryer can quickly dry the wet material with a moisture of 60% to a dried product with moisture less than 12%. It can be used for drying wood chips, sawdust, bark, straw, alfalfa hay, husk, sugarcane bagasse, cassava residues, poultry manure, etc. And the final product can be applied in boiler combustion, gasification and power generation, animal feed, fertilizer, etc. We offer the whole biomass drying system including a heating machine, conveyor, feeding part, cylinder dryer, discharging part, and dust collector, etc.

High thermal efficiency, stable drying quality.

Long parts life, not easy to wear.

Simple structure, a small footprint.

Uniform vibration, airproof setting.

Exchange heat fully, lower the energy consumption.

Simple operation, environmental protection and energy saving.

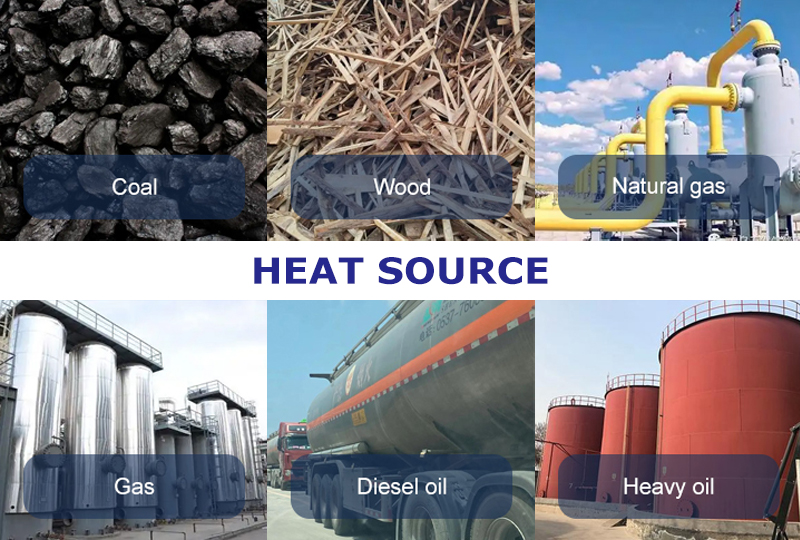

FTM dryers can support multiple heat sources and are easy to switch. The choice of heat source determines the operating cost of the equipment, so the choice of heat source needs to consider safety, environmental protection, material quality requirements, etc. The more common heat sources are mainly divided into three categories: solid fuel, gas fuel, and liquid fuel.

Solid fuel: coal, biomass pellets, rice husk, wood, etc.

Gaseous fuel: natural gas, biogas, coal gas, liquefied petroleum gas, waste heat flue gas, water vapor, etc.

Liquid fuel: diesel, heavy oil, biomass oil, etc.

Technical Specifications

| Spec./m | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Ø 1.2×8 | 1.9-2.4 | 700-800 |

| Ø1.2 ×10 | 2.4-3 | 700-800 |

| Ø 1.5×12 | 4.5-5.7 | 700-800 |

| Ø 1.5×14 | 5.3-6.6 | 700-800 |

| Ø1.5×15 | 5.7-7.1 | 700-800 |

| Ø 1.8×12 | 6.5-8.1 | 700-800 |

| Ø 1.8×14 | 7.6-9.5 | 700-800 |

| Ø 2.2×12 | 9.7-12.2 | 700-800 |

| Ø 2.2×14 | 11.4-14.2 | 700-800 |

| Ø 2.2×16 | 13-16.2 | 700-800 |

| Ø 2.4×14 | 13.5-16.9 | 700-800 |

| Ø 2.4×18 | 17.4-21.7 | 700-800 |

| Ø 2.4×20 | 19.3-24.1 | 700-800 |

| Ø 2.4×22 | 21.2-26.5 | 700-800 |

| Ø 2.6×24 | 27.2-34 | 700-800 |

| Ø 3×20 | 30.1-37.7 | 700-800 |

| Ø 3×25 | 37.7-47.1 | 700-800 |

| Ø 3.2×25 | 42.9-53.6 | 700-800 |

| Ø 3.6×28 | 60.8-76 | 700-800 |